Com o desenvolvimento contínuo de ligas de titânio, a expansão da variedade de produtos e a redução de custos, o uso de titânio na indústria civil cresceu exponencialmente. A Administração de Alimentos e Medicamentos da China (CFDA) classifica os dispositivos médicos em três categorias com base nos níveis de segurança, com implantes de titânio e ligas de titânio se enquadrando em Dispositivos médicos de classe III—classificados como bens de consumo de alto valor. Os principais subsetores com quotas de mercado superiores a 5% incluem diagnóstico in vitro, cardiologia, diagnóstico por imagem, ortopedia, oftalmologia e cirurgia plástica, com diagnóstico in vitro, ortopedia e intervenções cardíacas sendo os segmentos de crescimento mais rápido.

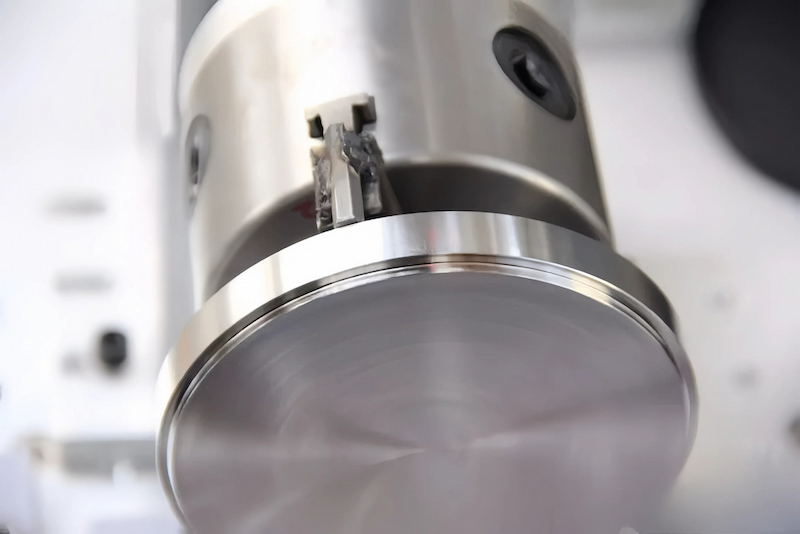

Produtos comuns de liga de titânio em implantes cirúrgicos e dispositivos ortopédicos

| Tipo de produto | Produto típico |

| Substituições de ossos e articulações | Cabeças femorais artificiais, articulações do quadril, articulações do joelho, articulações do tornozelo, articulações do ombro |

| Implantes Dentários | Fixações dentárias, dentaduras, bases para dentaduras e estruturas |

| Implantes Cardiovasculares | Stents vasculares, válvulas cardíacas, marcapassos |

| Implantes de Reparo Craniano | Placas de malha 2D/3D, parafusos ósseos, placas ósseas |

| Implantes de Fixação Óssea | Parafusos de fixação, placas ósseas, gaiolas de fusão intervertebral, hastes intramedulares |

| Implantes espinhais | Sistemas de fixação espinhal, sistemas de fixação toracolombar |

· Biocompatibilidade: Reação biológica mínima com tecido humano, não tóxico e não magnético, tornando-o seguro para implantação.

· Propriedades Mecânicas: Alta resistência e baixo módulo de elasticidade, assemelhando-se ao osso natural para reduzir a proteção contra estresse e promover a consolidação óssea.

· Resistência à corrosão: Material bioinerte que resiste à degradação em ambientes fisiológicos, garantindo estabilidade a longo prazo.

· Não magnético: Não afetado por campos eletromagnéticos ou tempestades, aumentando a segurança do paciente.

· Leve:As ligas de titânio são 43% mais leve que o aço inoxidável, reduzindo a carga sobre os pacientes.

A evolução das ligas de titânio biomédicas passou por três fases principais:

· Titânio puro e Ti-6Al-4V (década de 1950): As primeiras aplicações incluíam placas ósseas, parafusos e articulações do quadril. O Ti-6Al-4V tornou-se amplamente utilizado em reparos cirúrgicos.

· Ti-6Al-7Nb (década de 1980): Substituiu o vanádio (V) devido a preocupações com toxicidade. A empresa suíça Mathys o adotou para hastes intramedulares e parafusos ocos para fraturas do colo do fêmur.

· Ligas porosas de Ni-Ti (PNT) e Beta Titânio:

o ACTIPORE™ (BIORTHEX do Canadá): Gaiolas porosas de fusão de Ni-Ti para lesões na coluna vertebral.

o Ti-13Nb-13Zr: Melhor biocompatibilidade e menor módulo de elasticidade, expandindo aplicações em ortopedia, odontologia e intervenções vasculares.

O setor de dispositivos médicos ortopédicos contas para 9% do mercado global de dispositivos médicos e continua a crescer rapidamente.

O mercado ortopédico é segmentado em trauma (34%), articulações (28%), coluna (20%) e outros (18%).

· Substituição de quadril e joelho dominar (>95% do mercado global conjunto), com 1 milhão de pacientes anualmente passando por esses procedimentos.

· Placas de joelho de titânio são mais leves e resistentes à corrosão do que o aço inoxidável, impulsionando a mudança para próteses de titânio.

· Gaiolas de fusão intercorporal (50% do mercado de implantes espinhais) são cruciais para a substituição do disco.

· "Ossos artificiais" de titânio integra-se ao tecido natural — o osso cresce novamente em titânio poroso e os músculos aderem ao implante, fornecendo suporte estrutural.

· Garras de patela de titânio são implantes com memória de forma: resfriados para moldagem, eles apertam ao serem aquecidos para proteger rótulas fraturadas.

O titânio revolucionou os implantes dentários devido à sua compatibilidade óssea, resistência e conforto leve.

Na odontologia, o titânio puro era originalmente utilizado, mas não atendia às necessidades de retificação de precisão. A indústria então migrou para a liga Ti-6Al-7Nb, agora certificada pela ASTM. Hoje, as ligas de titânio compõem quase todas as peças metálicas de próteses dentárias. de coroas e pontes a grampos e pinos de implantes. Eles agora são o padrão para componentes críticos como implantes dentários e bases de dentaduras de porcelana.

Produtos odontológicos comuns de titânio

Tipo de liga | Formulário do produto | Aplicações |

Titânio puro | Fundições | Coroas dentárias, pontes, incrustações, dentaduras, bases de dentaduras, raízes de dentes artificiais, inserções de implantes |

Titânio puro | Peças prensadas a frio | Bases de dentaduras |

Titânio puro | Peças de metalurgia do pó | Raízes de dentes artificiais, inserções de implantes |

Titânio puro | Peças com formato especial | Instrumentos cirúrgicos |

Ti-6Al-4V | Fundições | Dentaduras, bases de dentaduras, raízes de dentes artificiais, inserções de implantes |

Ti-6Al-4V | Peças moldadas em superplástico | Dentaduras, bases para dentaduras |

Ti-6Al-4V | Peças de metalurgia do pó | Raízes de dentes artificiais, inserções de implantes |

Liga Ti-Ni | Fios | Fios ortodônticos |

Ti-29Nb-13Ta-4,6Zr | Fundições | Dentaduras, bases para dentaduras |

· Válvulas cardíacas, stents e marcapassos confie na durabilidade do titânio.

o A demanda da China: 250 mil substituições de válvulas/ano (apenas 25 mil realizadas); marcapassos (40 mil necessários, 2 mil fornecidos internamente).

o Stents coronários têm uma taxa de produção nacional de 50%.

· Ferramentas não magnéticas e resistentes à corrosão: Bisturis, fórceps, brocas ósseas e agulhas de sutura.

· Dispositivos especializados: Eletrodos de ECG, filtros de oxigênio e sondas ultrassônicas.

As ligas de titânio são transformando a medicina moderna—melhorando a longevidade do implante, a precisão cirúrgica e os resultados dos pacientes em ortopedia, odontologia e cuidados cardiovascularesCom os avanços contínuos, o papel do titânio na área da saúde deve se expandir ainda mais.